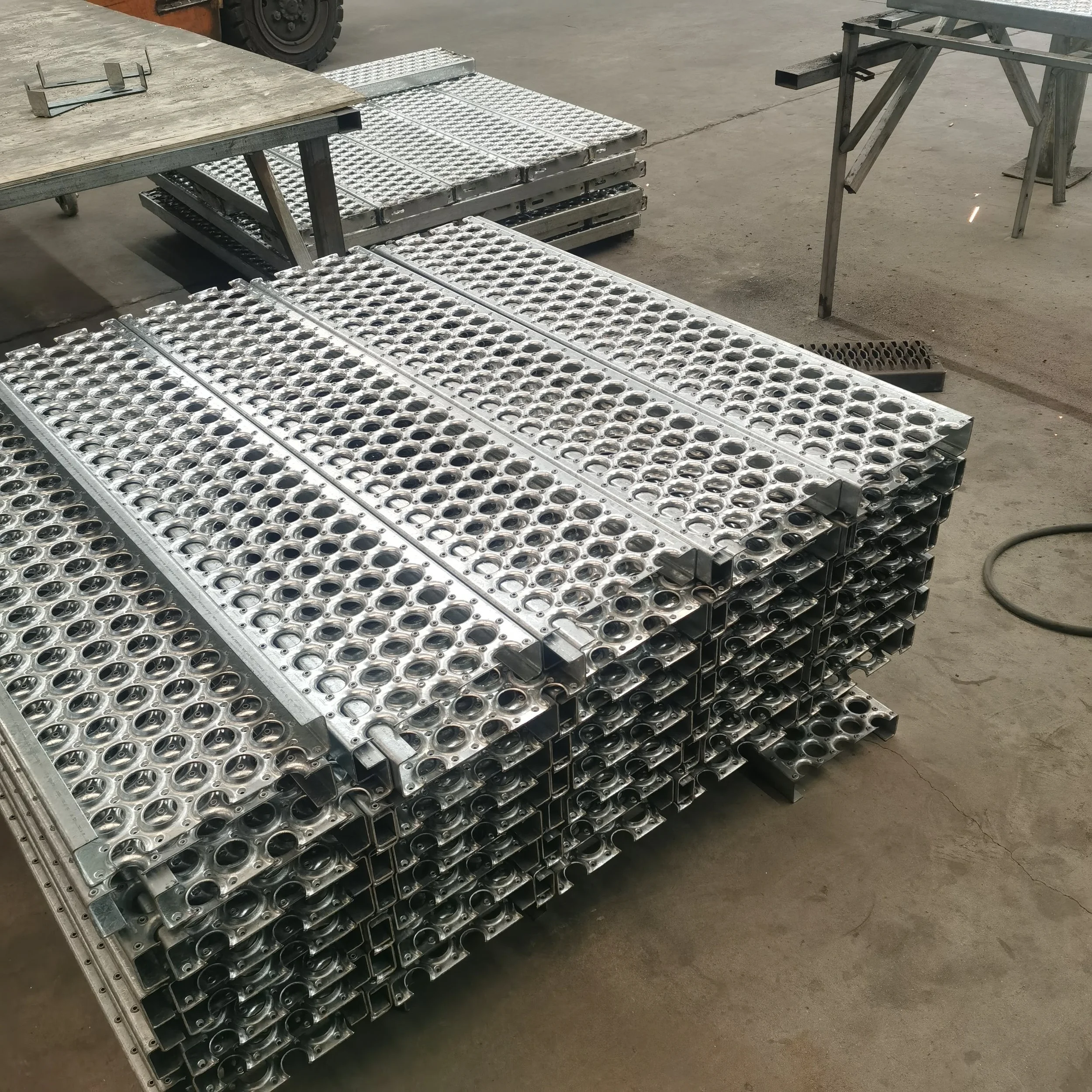

safety Grating

Safety grating is a lightweight, slip-resistant flooring and walkway solution designed for maximum traction and safety in industrial, commercial, and public environments. Available in galvanized steel, aluminum, and stainless steel, safety grating provides durability, corrosion resistance, and low maintenance.

PRODUCT SPECIFICATIONS

-

Galvanized Steel: Strong and economical with corrosion protection

Aluminum: Lightweight and corrosion-resistant for easy handling

Stainless Steel: Superior durability and chemical resistance for harsh environments

-

Diamond Tread: Aggressive slip resistance for heavy-duty applications

Open Tread: Maximum drainage and ventilation, ideal for outdoor and wet conditions

Dimple Tread: Raised surface for multi-directional slip protection and pedestrian traffic

Traction Tread Ladder Rungs: provide a strong, slip-resistant climbing surface for safe access in industrial, commercial, and marine environments.

-

Mill finish, galvanized, anodized, or stainless polish

-

Standard lengths and widths available; custom cut-to-size panels on request

-

Available in multiple gauges depending on load requirements

-

All types of fasteners are available upon request, depending on the application.

spec sheets available upon request

Safety grating applications

-

Residential

Safety grating delivers slip-resistant flooring for platforms, catwalks, and mezzanines in factories, mills, and refineries—ensuring worker safety in demanding environments.

-

Industrial

Lightweight and durable, safety grating is ideal for pedestrian bridges, drainage covers, and access walkways—providing secure footing and efficient water or debris passage.

-

Commercial

From stair treads and ramps to high-traffic entrances, safety grating offers long-lasting slip resistance and dependable safety in both indoor and outdoor public spaces.